We have been selling interfacing and stabilizers at Serial Bagmakers for a long time. We are in Europe and sell worldwide. We are known for researching each and every product we sell so your sewing projects will have the stability and structure you envisioned. To help you decide which interfacing or stabilizer you need we will try to shine some light on this subject and make it easier for you to choose the right product for your project.

We’ll compare the items we sell with other items in the market.

We sell woven and non-woven, fleece, foam, light, sturdy, fusible, sew-in and self-adhesive stabilizers. And yes, we sell Vlieseline G700 and Decovil.

How a bag looks depends only partly on the fabric you use, the way a bag stands is primarily based on the interfacing and stabilizer material you use. Below you can find information on the products we sell and will be able to choose the correct product for your bag to have the structure and feel you want.

Why would you use interfacing and stabilizer?

You do not want a bag that collapses like a pudding unless you make a boho bag. On the other hand do you want a bag that is so stiff you cannot turn the bag after sewing?

You will need to reinforce your bag when you place rivets,bag feet, a lock, or straps so stress points are sturdy and wear well. So, the question you should ask yourself is which reinforcement is the best for the bag I will make?

To make your fabric ‘fit for bagmaking’

To make a bag, you can use any material that you to achieve the bag of your dreams. I have seen bags made from wood!

Cotton (quilting or upholstery), canvas (coated, waxed, or plain), faux leather, cork, or genuine leather are materials commonly used for bag making and each differ in weight, stiffness, backing (coating), etc. So, your interfacing/stabilizer needs to suit the material you choose.

Fabric with little or slight stretch is the most common for bag making but with the proper reinforcement, you can turn French terry or knit fabric into a material fit for bag making.

In this document , we will not go into making bags from genuine leather. That is a whole other level of bag making. Totally different types of interfacing/stabilizers are used and adhesion to leather is different from fabric.

To stabilize your fabric bag so it stands or falls as you envision it.

The perfect bag with the ideal structure. It’s not the same for everyone. Some like a bag to fall along their body like the boho style. Another person may want a bag to stand up straight even when the bag is empty. Some like their bag to have some body and others want a floppy bag. A laundry basket has different requirements than a small toiletry pouch. And a spacious shopping bag must fall differently than a small crossbody.

The reinforcement used for your bag depends on what you want your bag to look like and what fabric you will use.

We hope to give you pointers so you can tackle your next project and learn how to choose the proper reinforcement based on how you want your final project to look and feel.

When you make a pattern for the first time, AND you use the same material as the designer, AND you want to achieve the same effect, go with the recommended interfacing/stabilizer the bag designer recommends.

When you deviate from the fabric and interfacing suggested or want a different effect, use the stabilizer and interfacing information below as a guideline to create the effect you want.

What is the difference between stabilizer and interfacing?

Reinforcement in a bag has several functions.

Interfacing modifies the materials’ structure (stretch, weight, and fragility). So, if you want to work with a thin, fragile fabric, you need a different kind of interfacing than when you work with artificial leather. If you are working with a fabric with a slight stretch then it’s appropriate to interface it to remove the stretch. Interfacing is usually applied directly to the fabric, usually with a heat-sensitive adhesive layer so the interfacing adheres to the fabric using heat from an iron.

A stabilizer is used to shape the bag. If you are making a basket for your table it is appropriate for the sides to stand upright. If you are making a large travel bag, you may want to store it conveniently and be able to fold and store. A simple shopping bag should fold and fit into your handbag. A handbag should keep its shape nicely even when empty. You get the picture. You achieve that shape by putting materials between the outer and lining fabric. Your project may need iron in interfacing/stabilizer or sewn in interfacing/stabilize. Very often, you achieve a far better result with sew-in stabilizers.

When designers or fellow bag makers talk about stabilizers and interfacing they usually speak in general terms. Some materials stiffen and shape or help your bag to have a soft draping effect so your options are not always black and white. When you think about the appropriate ‘reinforcement’ for your bag, it helps to consider both stabilizer and/or interfacing.

Types of fabric reinforcement

In terms of reinforcement a distinction is often made between woven and non-woven materials.

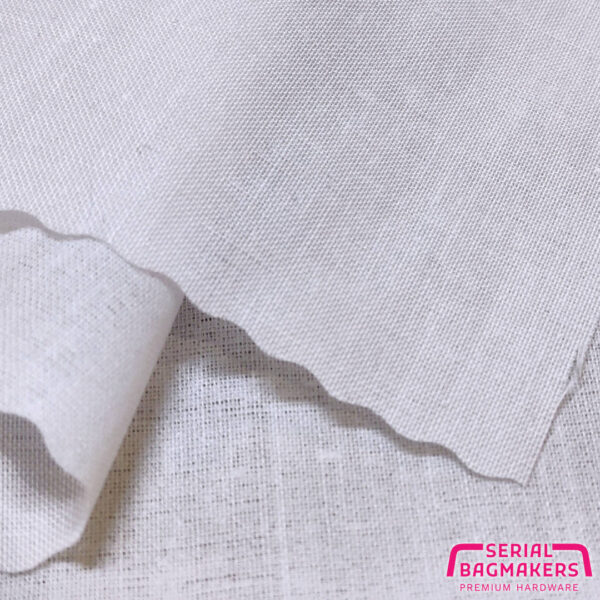

Woven reinforcements

Woven interfacing is a fabric that feels and flows like fabric and is also very strong. It also has a thread direction. If you want to use a thin fabric for bag making but the bag or pattern calls for a thicker canvas-like fabric it is best to reinforce it with woven interfacing. If you already are using a thicker material than recommended then you can often omit woven interfacing. Think of thicker canvasses (waxed or not), non-stretchable artificial leather, cork leather, etc. Woven reinforcement is also appropriate to take any stretch out of the fabric. Remember that woven interlocking reinforcement does have a thread direction. To add stability, we have Quickfuse Skin (light), Quickfuse Light (light), Vlieseline G700 (light), Quickfuse Soft (medium), Wovenfix2 (medium) To add stability we sell Quickfuse Canvas (Heavy).Non-woven reinforcements

Non-woven reinforcements come in different types. The thinner variants can tear more easily than woven reinforcement and are rarely used for bags. The thicker variants have their individuality, ranging from a paper-like feel to leather-like. The thicker ones are often used when you want to give more structure or shape to your fabric. The disadvantage of these stabilizers is that they often give a more wrinkled look to the outer fabric than woven reinforcements. This wrinkled look can be partially avoided by reinforcing the outer material first with a layer of woven lining of adding the stabilizer to your lining.

We have the following stiffeners in stock: Bouncyfirm 160 lux (medium), Decovil light (strong), Bouncyfirm 210 (strong), Decovil I (very strong) and Easy web (peel and stick).

The firmer the reinforcement, the more shape it gives. But also, the firmer the reinforcement, the harder it is to birth your bag.

Point reinforcement

You can stabilize your entire bag, just one panel, or only specific places. It is recommended to

reinforce your material where there are points of stress. Examples are the starting point of your

handles or where you make a hole for rivets, bag locks, grommets, or purse feet. The last thing you

want is for the fabric to tear or fray at those points. Sometimes, a thin layer of fusible woven

interfacing is sufficient. It is better to be safe than sorry and you may choose use piece of Decovil

Light for high stress points. I save all scraps of Decovil light for this purpose. No need to buy

expensive Wonder dots which are nothing more than pre-punched rounds of Decovil light.

Types of stabilizer

If you need to bag to drape or have a small amount of structure

These stabilizers give body to your bag. The thicker versions will also give shape. They exist in

fusible and sew-in varieties.

The thinner versions like fusible fleece are ideal for bags that may fall along the body and not have

to stand up. Some bags need a little more body than outer and inner fabric ‘exposed’ against each other. A fusible fleece-like stabilizer is the ideal reinforcement for a simple tote bag made from plain canvas or interfaced quilting cotton fabric.

This type of reinforcement is often sufficient for smallish bags made of outer materials that already

have a bit more standing (e.g., thinner artificial leather, waxed canvas, etc).

We sell Fusible fleece and Ronofix One. Both versions are fusible.

If you need your bag to stand tall

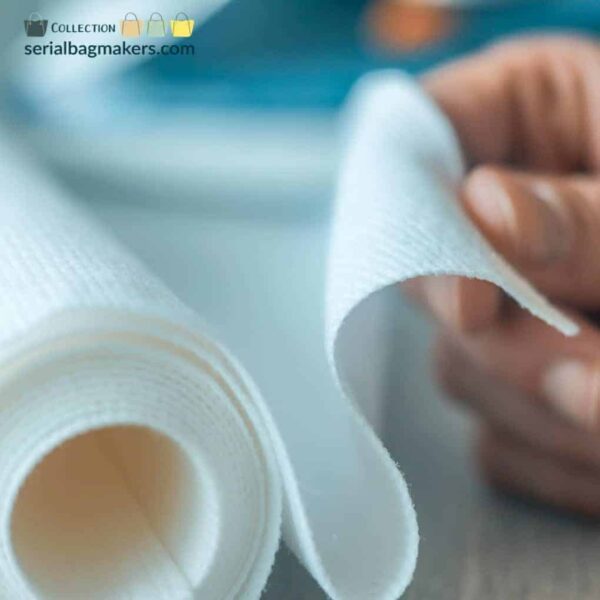

Foam-like stabilizers are explicitly made for bags.

They feel like a mousse, covered by a thin layer of tricot glued to one or both sides. The thickness

varies from 3 to 4mm and can compress to 1mm, so it can still be maneuvered perfectly under any

sewing machine. This stabilizer is lightweight and gives shape to your bag, and your bag will jump

back into that shape. Your bag will stay open and keep its shape without being filled. You will

especially appreciate this stabilizer.

Foam will also reinforce laptop compartments and tablet sleeves, because the foam still offers some

protection, Even for the back panels in backpacks or extra shoulder pads in bag straps it proves it’s

use.

Foam exists in sew-in and iron-on versions. If you choose sew-in, you cut the stabilizer in the same

size as the part to be reinforced and then attach it to the fabric seam with a zigzag or overlock

stitch (this way, you push the foam flat in the seam and avoid bulk). Then treat that part as a pattern

piece.

Since there are many downsides on the iron-on version, we choose to not offer them in our store.

When using Foam, you will still need to reinforce the outer and inner fabric’s stress points with ironon

(point) reinforcement like Decovil LIght.

Foam will shape your bag but will not prevent the material from tearing.

We sell Vlieseline Style-vil (sew-in).

To add extra stiffness

We are talking about form-fitting pressed reinforcement, foam, plastic, wood, and acrylic.

These materials are specifically designed to give shape and strength to bags, bottoms, flaps, pockets, etc., and they range in strength from light to very strong. Some are glued (on one or both sides), and some are sew-in. Others are placed loosely between the layers or inside the bag.

We carry Easyfoam 2mm (self-adhesive) and Quick2fuse Heavy (thermal glue on both sides)

For bag bottoms we like plastic cutting mats. Nothing fancy, affordable, and available everywhere.

Does the brand make the quality?

In 2024, that is not the case. Two top brands are Vlieseline (Europe and Asia) and Pellon (America’s)

and are the best-known brands, so pattern writers often mention the interfacing and stabilizer

names from those brands. Such as Vlieseline H630 or Pellon 987F. Others use more general terms

such as volume lining or ‘fusible low loft fleece’.

At Serial Bagmakers, we sourced our own brands of top products. They come from smaller-scale

manufacturers.

Never say ‘Vlieseline’ to bag reinforcements. The subject is not sexy, but it makes your bag stand or fall. Literally.

Since feeling says so much more than words, we offer a swatch-card of all the bag reinforcements.

We have prepared a discovery box with 50cm of all the (newer) stabilizers and interfacings. We left out th emost obvious interfacings (Vlieseline G700, Style-vil, Decovil Light and Decovil Heavy) assuming you already know them. It’s always possible to add it yourself when you order the box.

You will receive a swatch card of ALL the reinforcements.